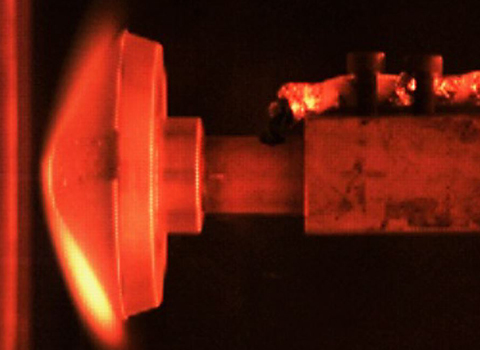

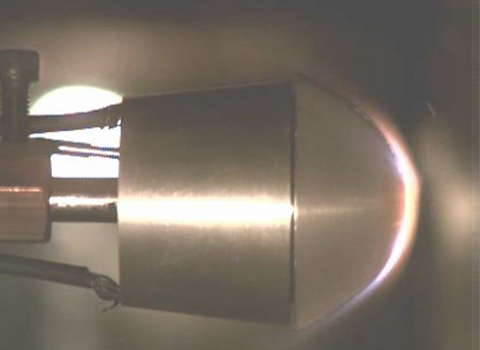

AERODYNAMIC TESTING

MACHSTAR provides services for aerodynamic testing of models up to Mach numbers of 10. Surface pressure distribution, discrete convective heat transfer, lift and drag forces, pitching moments (along all three axes) are some of the measurements that can be obtained. High resolution high-speed schlieren images can also be acquired in these tests.

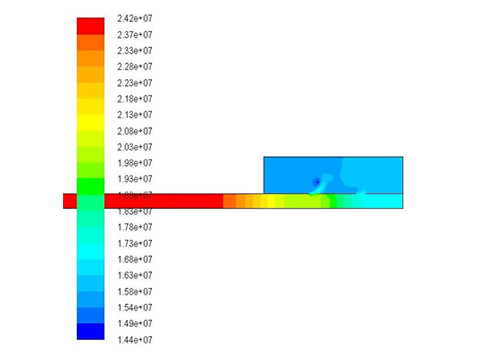

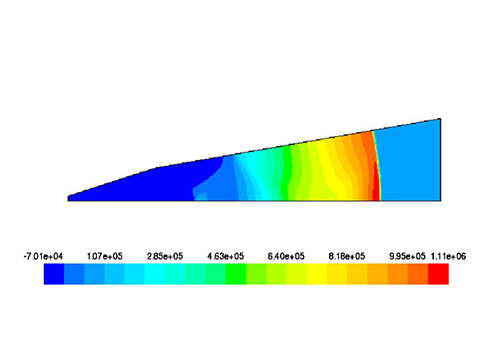

CFD ANALYSIS

CFD simulations using ANSYS Fluent of shock laden flows including supersonic and hypersonic flows over simple aerodynamic models. We specialize in simulations involving shock tubes, explosions (simulating the pressure effects), projectile acceleration, and conjugate heat transfer. A report on the relevant parameters will be provided.

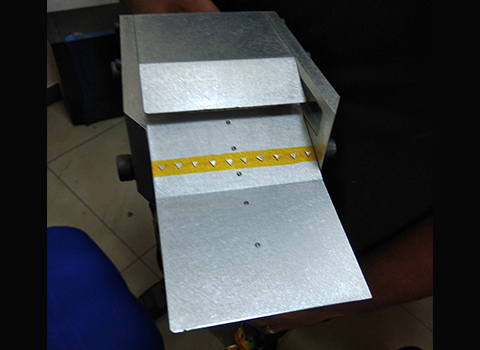

SHOCK IMPACT ON SAMPLES

Shock loading on specimens is relevant for qualifying certain components for blast/explosion proof certification. We provide services to load any specimen using shock tube with a prescribed shock load (up to 80 bar) and decay time (from 4 milliseconds to 20 milliseconds). Shock conditions having a longer duration (approx. 1 second) may be simulated upon request using a combination of a shock tube and fast open valves. Impact on solid plates/structures for long durations (>10 milliseconds) may be conducted using a specialized equipment, called BlaST (Blast loading using Shock Tube) simulator

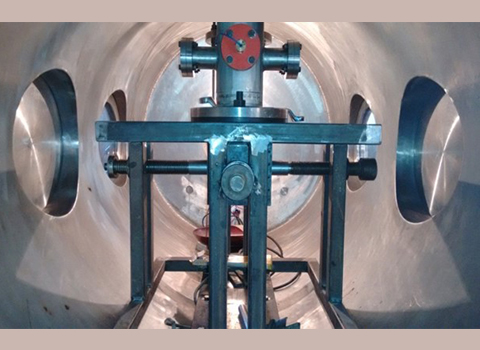

PRESSURE/VACUUM TESTING

Electronic components or other systems can be subjected to high pressure or high vacuum depending on the requirement. For high pressure testing, the maximum space of the test chamber available is 0.5 m in diameter and 0.5 m in height. Pressures up to 20 bar can be achieved. Virtually any gas or liquid can be used as the working fluid for testing. For vacuum tests, the maximum space available is 1 m diameter and 1 m length. Sustained vacuum levels of 0.001 Pa can be attained. Provision can be made for electrical line outlet from both systems if necessary.

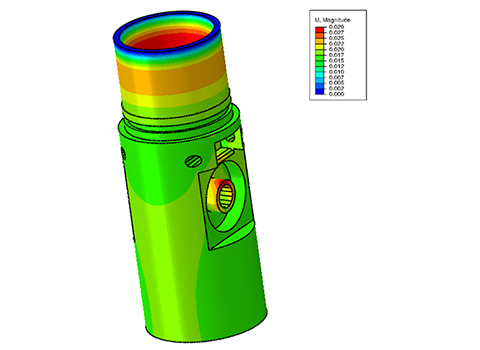

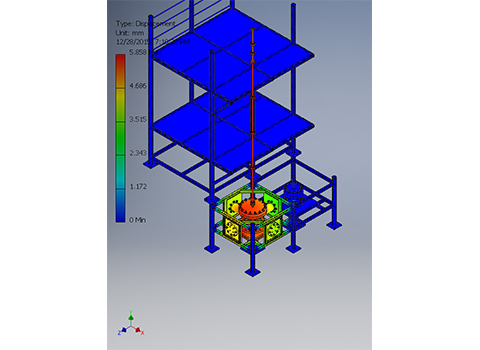

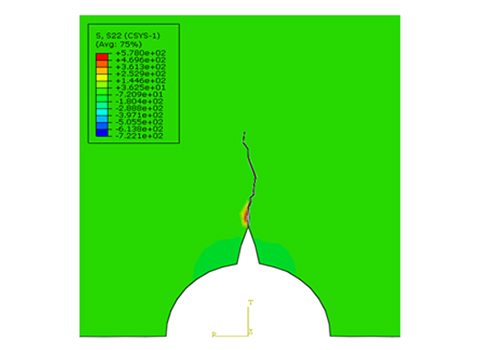

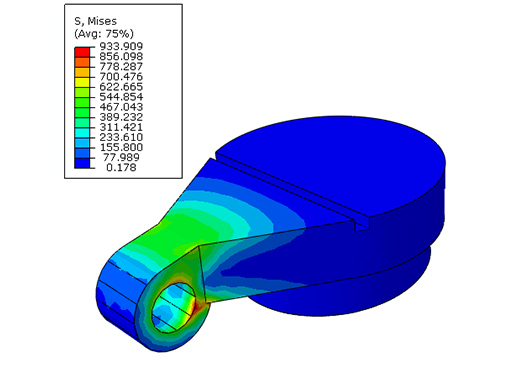

STRUCTURAL ANALYSIS

We carry out ABAQUS/Explicit simulations involving high strain rate deformation especially on blast loading of metallic and concrete structures. General contact simulations, involving collision/impact, liquid/structure impact are also carried out. The goal of these simulations is to provide key insights to the engineer regarding optimizing the design of a structure using simple models rather than going into the minutiae of the mesh generation and other such details.

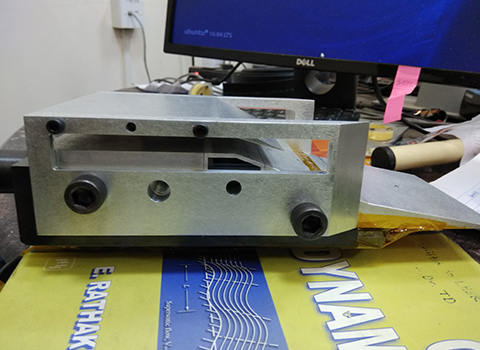

PROJECTILE IMPACT ON SAMPLES

Impact studies are essential in material development studies which involve high strain rate of loading. Projectiles of up to 50g can be launched onto the test specimen at speeds of up to 500 m/s. For lower velocity impacts, heavier masses, even up to 1 kg may be launched. The diameter of the impactor can have a diameter up to 135 mm. The 2D strains developed due to the high-speed impact may be measured using a high-speed camera (up to 40,000 fps) and digital image correlation software

BIOLOGICAL TESTING

Microbiology assays – Quality testing of products by classical & sophisticated techniques like PCR and Imaging. Microbial contamination detection. Molecular Biology assays – qRT PCR based assays to detect microbial strains. Gene expression analysis.

Tissue Culture based assays – Wide-range of cell lines are used for drug and molecule testing. Anti-cancer drug screening, growth factor development and validation.